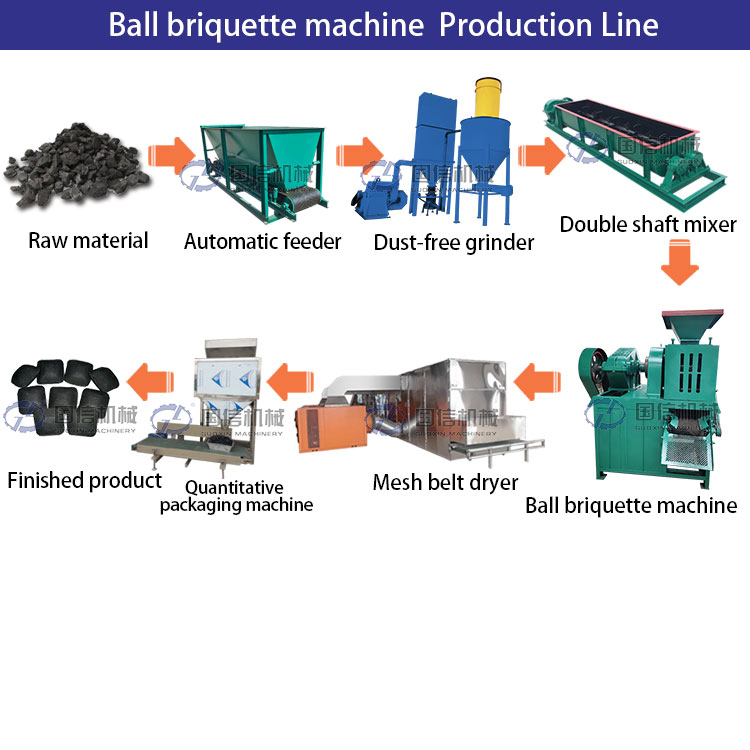

Ball Press Briquette Production Line

The Ball Press Briquette Production Line is designed for industrial powder briquetting, suitable for coal, lignite, mineral powders, aluminum powders, and industrial dust.

This turnkey line includes powder preparation, mixing, ball pressing, drying, and cooling, providing stable, high-density briquettes for fuel or recycling.

Coal powder

Lignite

Mineral powder

Aluminum powder

Dust and ash

1. Feeding quantitative machine: A forklift can be used for feeding. The function of the feeding quantitative machine is to make the whole line work evenly. There is a binder bin installed next to the feeding quantitative machine. A certain amount of raw materials and binders enter the mixer together.

2. Mixer: Make the material and binder fully mixed. At the same time, the density of the material can be increased during the mixing process, which makes it easier to make balls.

3. Ball press: The ball size can be designed to be 30-60 mm, and different shapes can be made according to your requirements. It can process 1-40 tons per hour. The pressure of the machine is adjustable, and the working pressure is usually 40-50 tons.

4. Dryer: The moisture content of the formed agglomerates is about 25-30%. The moisture content can be reduced by a dryer, and the finished products can be directly packaged and sold.

Briquette shape and diameter

Production capacity

Automation level

Binder type and ratio

Finished product display

All powder materials can be pressed into various shapes, including round, oval, square, egg, diamond, pillow, etc.