Product Introduction

Our aluminum powder ball press machine is a roller press type. This aluminum powder ball press can exert higher pressure, thus producing briquette with higher density. These briquette can be designed into shapes such as oval, egg, pillow, square, etc. This aluminum powder briquette machine is widely used in coal industry and metallurgical industry. High pressure is provided by hydraulic components to ensure high density of the product.

Working Principle

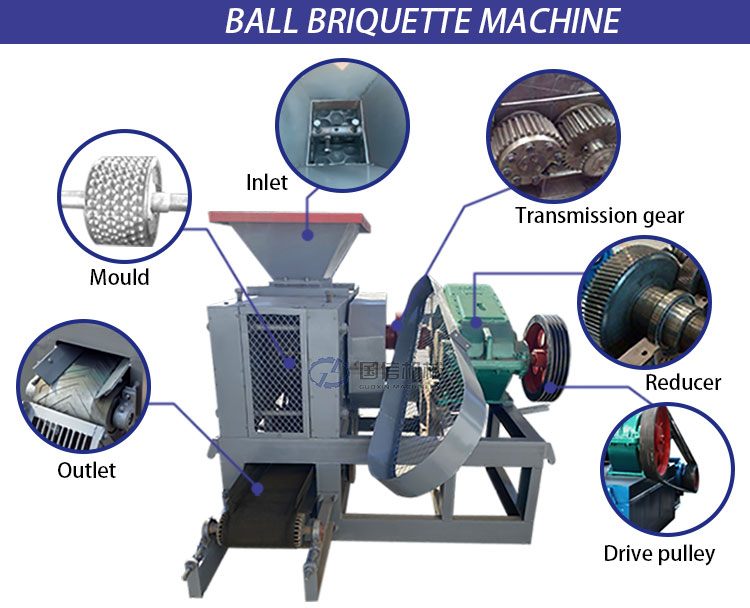

The machine uses a hydraulic system to compress powdered raw materials such as aluminum powder and charcoal powder into pellets. The hydraulic system applies pressure to the piston to compress the material inside the machine, producing pellets of different shapes and sizes. The machine has a mold that is used to give the pellets the shape required by the user.

Product Advantages

1. High production capacity: Depending on machine specifications and materials, the basic pellet briquetting machine can produce up to a thousand pellets in one hour.

2. Long life: Made of high-quality materials to ensure long-term stable operation of the machine with few failures.

3. Easy to operate: The operation interface is simple, with few buttons and switches, and is user-friendly.

4. Excellent briquettes: The briquettes produced have high density and are easy to burn, and can be used in a variety of scenarios.